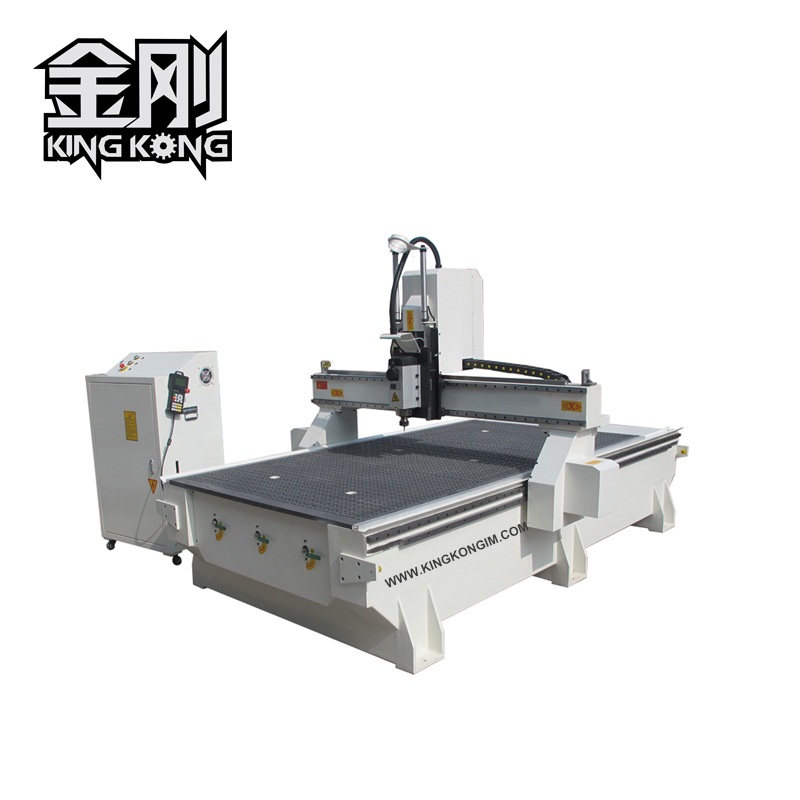

ACTION C1

ACTION C1

- Detail

Main Technical Parameters

Model | ACTION -C1 |

Machining Area | 1300x2500mm |

Running Speed | 50m/min |

Spindle Motor | 6.0kw air cooling spindle |

Z Axis travel | 180mm |

Driving System | Syntron servo drive and motor |

Guide Rail | TAIWAN guiding rail (Y /X/Z =25mm) |

Rack and pinion | Helical rack and pinion for X and Y axis transmission |

Ball Screw | Taiwan TBI ball-screw for Z axis transmission |

Cutter | ∮6 ,∮12.7 |

Power Supply | AC380V/50~60HZ |

Inverter | 5.5kw Inverter 380V 3phase |

Weight | 2000KGS |

Control System | DSP control system: NK105 (Optional NC Studio 53C control system) |

Table | Vacuum table with T-Slot(Optional aluminum working table ) |

Pump | 5.5kw air pump with stable quality(Aluminum working table without pump) |

Oil supply system | Semi-automatic |

MORE DETAILS OF MACHINE PRODUCE:

1,The gantry andthe Z axis with scientific design.

2. Milling the groove for X,Y Axis afterwelding,Install the Rail and rack in keep a good accuracy .

3Install the Rail and rack base on theGroove for x/y axis, with high precision rack .

4.Chinese Servo drive and motor, verystable quality and cost performance.

5.High quality vacuum working table,up to 6-8 mm deep air channel, sealed adsorption rubber strip, big power pump, keep a super strongadsorbability.

6.Also can be choose the vacuum table withT-Slot. Can be adsorpted and with work with claps too.

7.IFyour material is Acyrilic or soft aluminum material, can be choose the aluminumworking table as following picture :