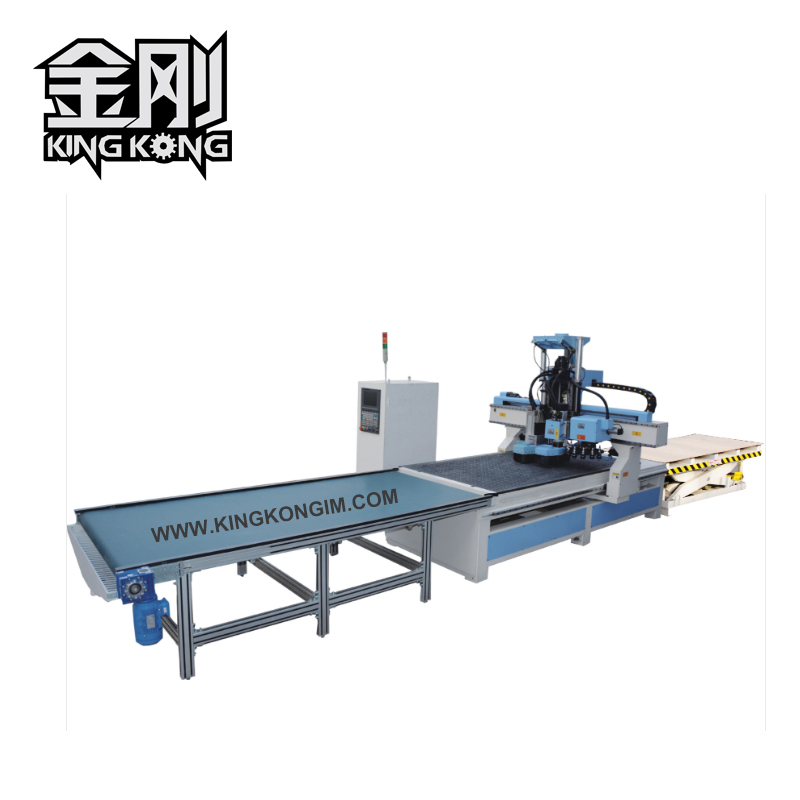

KINGKONG PY12

KINGKONG PY12

- Detail

Main Technical Parameters

Model | KINGKONG PY12 |

Machining Area | 1300x2500mm |

Z axis Travel | 200mm |

Running Speed | 50m/min |

working sytle | XYZ transmission |

Spindle Motor | 9.0kw ATC spindle (0~24000rpm)(Optional) |

ToolMagazine | Carousel design(revolver tool-changer) with 12 tool holders |

Boring Head | Vertical drills up to9(4X-5Y)6000rmp |

Control system | Taiwan SYNTEC controller |

Driving System | Japanese Yaskawa servo motor and driving system Y=1800w,X=1300W,Z=2505 |

Guide Rail | Taiwan (30mm for Y axis and X axis and 25mm for Z axis) |

Ball Screw | Taiwan TBI ball-screw for three axis transmission (Φ40 for Y axis ;Φ32 for X axis; Φ25 for Z axis) |

Power Supply | AC380V/50~60HZ |

Inverter | 11kw inverter with good quality |

Table | Vacuum table with T-Slot |

Pump | 7.5kw air pump with high quality |

Oil supply system | Automatic |

Automatic Feed in | Automatic loading and unloading system |

Collet chuck | 6mm, 12.7mm |

CNC/components Warranty | Spindle motor is for half a year, others for one year. |

More details forthis model machine as following:

1,Optionalwith the Carousel design, as following details picture:

2.Taiwan SYNTEC 20MA control system, which has apowerful numerical control with multitasking capability, interface with openhumanized design. Big memory capacity, may directly output for processing, Donot need one side transmission and at same time processing. The modern softwareinterface makes particularly easy and direct the machine programming. Perfect PLC control used in all kinds of world high-end CNCequipment operation.

3.Japanese YASKAWA servo drives and motors, has high precision and goodanti-jamming capability, higher torque, when making heavy cutting, the high performanceof the servo motor can provide more powerful motivation, higher speed of plusor minus, so as to shorten the cycle time. High resolution encoder and digitalclosed-loop feedback to ensure the high precision positioning. It is the bestchoice for high-end model machine.

4.High quality 9KW air cooling spindle motor with Italy technical, high speed, low noise, waterproof anddustproof test. Its internal bearing the Eruope original heat resisting ceramic bearing, speed up to24000 rpm/min. Spindle to install high flow, ultra-quiet fan and the fan toinstall a speed sensor is used to detect whether the cooling system to worknormally.

5.Adopt high quality millingplate for Z axis, has good shock resistance, good wear resistance, good machinability, low notch sensitivity. Can effectively absorbvibration energy; Small linear shrinkage rate and volume shrinkage, againstdeformation and cracking.

6.Classical Boringhead with high quality. Optional HSD is Italy's leading CNC manufacturer, it have a variety of models for the boring-mill work of point to point,containing a vertical spindle, horizontal spindle and cutting unit. Elliptical cylinder with special designed to promote the spindle to the work position , that can be increased to 35% of the thrust than traditional cylindrical cylinder. HSD boring head with a series of separate remote control valves, and only one control cable, reducing individual connection of each boring head.

7.Automatic loading and unloadingsystem:

8.Steel heavy structure, the whole steel plate wleding platform, stableand no deformation, strong dsorption capacity.

9.Automatic loading and unloading system(Optional)

10.Schneider Electric CO., LTD. is one of the world'stop 500 enterprises, the world's top electric enterprises. Schneider protectoris with multiple protection function (overload, short circuit, under voltageprotection, etc.), action value is adjustable, high breaking capacity,convenient operation, and safety. It is the best choice in electrical control.

11.Taiwan AIRTAC air handling unit, double filter structure, usingcentrifugal filtration and replace HDPE mesh filter element to recycle.Separate the air and water very fast and small pressure loss. Liquid oil, waterand dust filtration efficiency is as high as 99.99%.