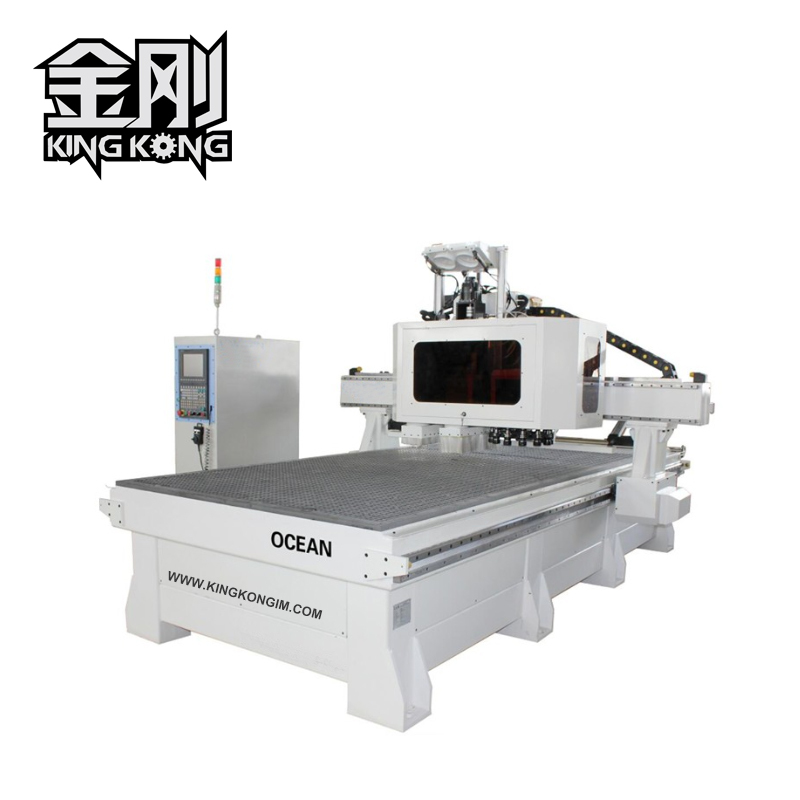

OCEAN PY12

OCEAN PY12

- Detail

Main Technical Parameters

Model | OCEAN PY12 |

Machining Area | 1300*2500mm (Optional 1600x3200mm/2000x3000mm) |

Z axis travel | 200mm |

Running Speed | 50m/min |

Spindle Motor | 9.0kw ATC spindle (0~24000rpm) |

Tool Magazine | Carousel design(revolver tool-changer) with 12 tool holders |

Driving System | Japanese Yaskawa servo motor and drivers |

Guide Rail | Taiwan TBI rail (Y axis=30mm, X/Z axis=25mm) |

Rack and pinion | Germany HERION helical rack with high precision |

Reducer | Japanese SHIMPO reducer |

Ball Screw | Taiwan TBI ball-screw for Z axis transmission |

Boring Head | Vertical spindles up to9(4X-5Y)6000rmp |

Power Supply | AC380V/3Phase 50HZ AC220V/3Phase 60HZ |

Inverter | 11kw Inverter with good and stable quality |

Control System | Taiwan Syntec 20MA controller |

Electric | Schneider electric parts |

Table | Vacuum working table with pop-up |

Vacuum pump

| High quality vacuum pump with big flow |

Weight | 2500kgs/3000kgs/3500kgs |

CNC/components Warranty | Spindle motor is for half a year, others for one year. |

MORE DETAILS OF MACHINE PRODUCE:

1.Heavyduty gantry frame, Steel heavy structure, the whole steel plate wledingplatform, stable and no deformation, strong dsorption capacity. unrivaledwelded Unparalleled wall welded arm,indestructible and with low maintenance.

2.Taiwan SYNTEC 20MAcontrol system, which has a powerful numerical control with multitaskingcapability, interface with open humanized design. Big memory capacity, maydirectly output for processing, Do not need one side transmission and at sametime processing. The modern software interface makes particularly easy anddirect the machine programming. Perfect PLC control used inall kinds of world high-end CNC equipment operation.

3.Japanese YASKAWA servo drives and motors, has high precision and goodanti-jamming capability, higher torque, when making heavy cutting, the highperformance of the servo motor can provide more powerful motivation, higherspeed of plus or minus, so as to shorten the cycle time. High resolutionencoder and digital closed-loop feedback to ensure the high precisionpositioning. It is the best choice for high-end model machine.

4.Choose Japan SHIMPO reduer, machine be driven by a motor with reducer andgear rack mechanism .This machine has the features of high precision and fastresponse.

5.High quality 9KW air cooling spindle motor withItaly technical, high speed, low noise, waterproof and dustproof test. Itsinternal bearing the Eruope originalheat resisting ceramic bearing, speed up to 24000 rpm/min. Spindle to installhigh flow, ultra-quiet fan and the fan to install a speed sensor is used todetect whether the cooling system to work normally.

6. Magazine Disc design with 12 sets of ISO30 holders, handleholder made by nylon and aluminum metal frame, so the handle structure, notonly much strength, and also high flexibility. Work withspindle synchronization, real-time change tools automatic.

7.Adopt high quality millingplate for Z axis, has good shock resistance, good wear resistance, goodmachinability, low notch sensitivity.Can effectively absorb vibration energy; Small linear shrinkage rate and volumeshrinkage, against deformation and cracking.

7.Adopt high quality millingplate for Z axis, has good shock resistance, good wear resistance, goodmachinability, low notch sensitivity.Can effectively absorb vibration energy; Small linear shrinkage rate and volumeshrinkage, against deformation and cracking.

8.Germany Herion rack is one of the threebiggest professional manufacturer of rack in the world, as the mechanicaltransmission industry’s pioneer, has experienced more than 110years of thedevelopment course, Herion rack produce through the tooth grinding processunder the world’s most advanced technology, It can achieve the highest accuracywith mass production in the world; Non- work surface using forming and grinding technology,keep more higher parallelism. Rack have the characteristics of high speed, high efficiency, high rigidity,high-precision, low noise, low maintenance, heavy-duty, long life.

9.Choose the high quality guide rail TBI by Taiwan manufacturers.Which to meet customer required high precision and long service life. runningvery smoothly with ball retainer, which can eliminate rubbing against betweenballs, enhance freedom of slide block and the slide rail, and low noise, goodquality, self-lubricating, dust free maintenance and excellent high-speed.Within 0.1MM assembly clearance will be automatically compensated by GuideRail. Guide rail and slide block are strict precision testing before and completeset original before leave.

10.Taiwan DELTA inverter usinghigh-frequency switching technology has made the motor running with smallnoise. A variety of protective techniques can improve the anti-interference andhigh response speed. Delta inverter is containing the brake circuit, with abraking resistor terminals. It can improve the reliability for the usecondition on start/stop of the high frequency or high/low speed variation.

11.Classical Boring head with highquality. Optional HSD is Italy's leading CNC manufacturer, it have a variety of models for the boring-mill work of point to point,containing a vertical spindle, horizontal spindle and cutting unit. Elliptical cylinder with special designed to promote the spindle to the work position , that can be increased to 35% of the thrust than traditional cylindrical cylinder. HSD boring head with a series of separate remote control valves, and only one control cable, reducing individual connection of each boring head.

12Automatic loading and unloading system(Optional)

13.Schneider Electric CO., LTD. isone of the world's top 500 enterprises, the world's top electric enterprises.Schneider protector is with multiple protection function (overload, shortcircuit, under voltage protection, etc.), action value is adjustable, highbreaking capacity, convenient operation, and safety. It is the best choice inelectrical control.

14.Taiwan AIRTAC air handling unit, double filter structure, usingcentrifugal filtration and replace HDPE mesh filter element to recycle.Separate the air and water very fast and small pressure loss. Liquid oil, waterand dust filtration efficiency is as high as 99.99%.

Applicable of our cnc router 1325 for engraving machine

1) Furniture: wooden doors, cabinets, plate, office and wood furniture, tables, chair, doors and

windows.

2) The wood products: voice box, game cabinets, computer tables, sewing machines table,instruments.

COMPANY PROFILE

Shenyang Hua Zheng Technology Co.LTD is located in Chinese traditional base---------------Shenyang ,It's a diversified company with research and development,production and manufacturing,sales.Our main products of the Company are CNC Router,CNC maching center and Irregular sanding machine,CNC shaped sanding line,and various kinds of automation equipment to meet the production requirements for different customers.

The company has always been adhering to the aim that"Technology creates value service to promote advantages,Quality utomost,Excellent service."Unity, innovation, progmatic.Endeavor is our ultimate pursuit.

Advantage of our company:

1.Experience and professional

2.Talented and passionate work team

3.high tech products

4.perfect after-sale service

5.warranty:1 years

Guarantee & Aftersales Service:

1.Guarantee for one year

2.24-hour technical support by email or calling

3.User-friendly English manual for machine using and

maintaining

4.Free technician training for large customers.

After sales services:

Normal machine is properly adjusted before dispatch. You will be able to use the mchines immediately.

You will be able to get free training advice towards our machine in our factory. You will also get free suggestion and consultation, technical support and service by email/fax/tel and lifetime technical support.

Delivery:

Within 20 days after the deposit money

Packing:

Wooden case or as your requirement

Payment:

15-30days after down payment or LC